Welcome to Pro-

1/32nd Saloon.

Any chassis powered by a hawk 7 or bb that meets BSCRA dimensions.

Any commercially available saloon car body that complies to BSCRA regs.

Formula 2, as per BSCRA F2 Class.

Hawk 7 and bb motors only.

1/24th Sports.

Any BSCRA approved production chassis powered by Hawk 7, Hawk 7BB, Hawk 9, Hawk9 BB or Brushless motors not exceeding 4000KV.

Any commercially available open or closed sports prototype body including High down force bodies, BSCRA wing height and axle width.

Please note;-

Competitors cars will be marked Pro or Am at tech.

Pro racers;-

Am racers;-

Races:-

The following dates are available. Each date can be a South & North venue

July 7th Raceway 81 (north)

August 4th

September 15th

November 9th Final National race centre (day before Southern 32 final

For race date enquiries please mail raceway81@btinternet.com

Tips.;-

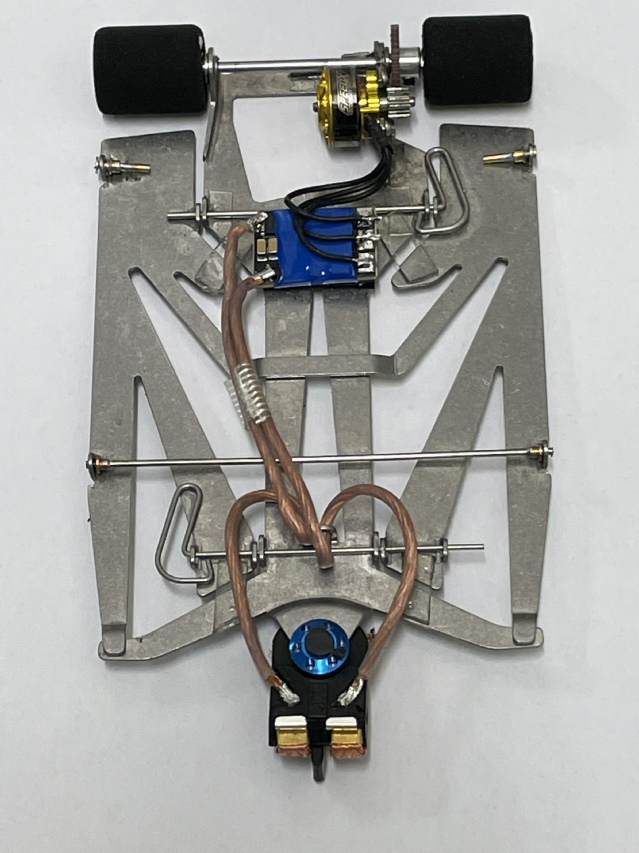

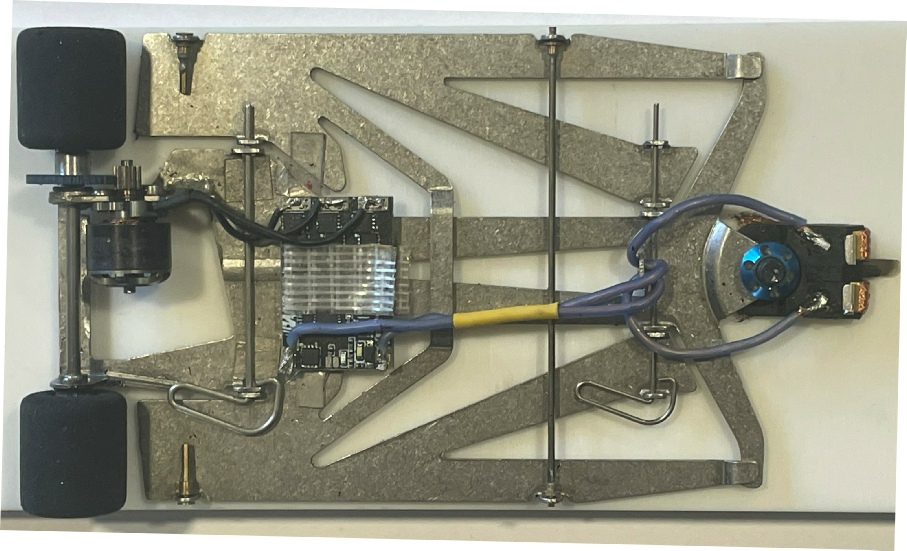

The Jk Chassis is stamped from 301 ½ hard Stainless. The AB adaptor bracket is 301 full hard stainless, so when soldering it is a good idea to use a stainless steel flux like the AB Stainless flux to ensure a good, strong job. Trim the bracket with a dremel to get the correct height for the motor to be used, ensure the motor does not sit lower than the chassis. The bracket , although full hard stainless can be bent to align the bracket hard against the pillar block and also provide a solder joint at the front (or just add a small infill) to do the same job.

Ensure the motor shaft is parallel to the axle and the motor shaft is inline with the axle. Generally you can adjust the gear ratio / mesh by moving the motor in the mount holes. We find a 37t 64p spur gear is the largest you need and pinion wise much depends on the track (tight corners or flowing etc).

Keep the motor wires short but do not put any strain on the motor wires as this may cause problems with the wire connections to the motor coils.

When fitting the motor DO NOT use screws longer than with a 3mm tread as this may damage the motor winding and kill the motor.

If you are using a single sided Board the best method of mounting is with double sided acrylic tape and strap of body tape around the centre of the board.

Don’t forget for this class the motors are restricted to 40000KV.

Mounting motors in an anglewinder configuration is not recommended.